By Jonathan Soudry on Friday 28 June 2019, 17:10 - Permalink

MANUFACTURING METHOD

1 - preparation of the Plasticine 50

Place the Plastiline 50 in an environment at least 20 degrees C. If not, heat the dough with a hair dryer.

Then cut a piece. Knead it well, to homogenize it and soften it.

2 - formatting the model

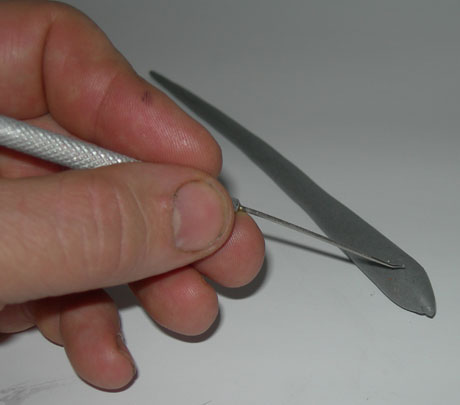

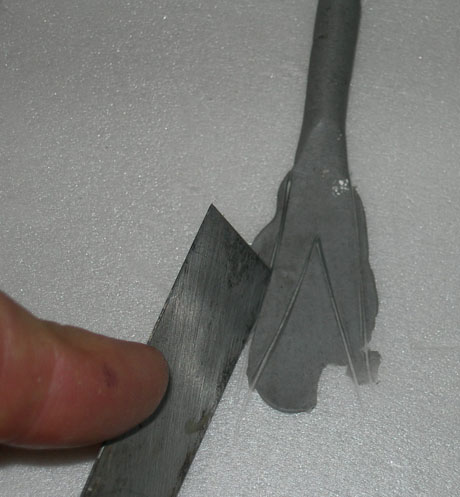

Depending on the desired shape, it is possible to roll, press, work with sculptural instruments.

As we go along, we work on the details, eyes, gills, slits to improve flexibility. The tail can be worked according to the imagination, depending on the desired movement.

3 - the moulding tank

Choose a plastic bin of the appropriate size. Ideally, there should be one centimetre between the edges and the model on each side. Allow a depth of 1 cm deeper than the thickness of the lure. It is not necessary to fill to the top of the bin. The vast majority of plastics are compatible with Bricoleurre silicone. Prefer a flexible plastic that will facilitate demoulding. E.g.: an old polyethylene lure box is perfect.

Glue the model to the bottom of the moulding tray to prevent it from rising to the surface of the silicone. Add the necessary amount of Bricoleurre silicone to a container to mix with the catalyst.

Add the catalyst: from 2% for a slow setting (12h) to 5% for a fast setting.

Shake it well for 2 minutes.

Brush the model with Vaseline.

4 - molding

Pour into the tray on the model, gradually to let the air bubbles escape. The silicone is liquid enough to fit all the details of the lure model. Tap the mold to ensure that all air bubbles rise. Allow to take a few hours (depending on the % of catalyst used).

5 - demolding

Unmold the entire tray and remove the model.