By Jonathan Soudry on Friday 28 June 2019, 17:09 - Permalink

WARNING

|

The preparation and heating of the Plastileurre produces an abundant and irritating smoke. It is strongly recommended to protect yourself with a mask and to operate in a well ventilated room or even outdoors. |

MANUFACTURING METHOD

1 - casting of the raw Plastileurre

Pour the Plastileurre into a saucepan placed on a gas fire, an electric stove or even a microwave. Pour a minimum thickness of 1 cm so that the whole thing can be shaken later

2 - heating of the Plastileurre

Heat by constantly shaking the Plastileurre until the liquid becomes transparent.

3 - addition of dye

Add drop by drop to properly dose the mixture while stirring.

4 - addition of iridescent powders

Shake to distribute the powder evenly until iridescent streaks are obtained in the liquid.

5 - addition of flakes

It is advisable to mix several colors of glitter to obtain more effective reflections.

6 - molding

Carefully pour the mixture into the mold, finishing with a slight bulge on top because there is always a retraction of the Plastileurre during cooling.

7 - insertion of a rattle

This optional operation is to be performed while the Plastileurre is still liquid.

8 - demolding

After allowing to cool for a few minutes, prepare the demolding by opening the edges to remove the lure from the mold.

9 - cooling

Immerse the warm lure in cold water to accelerate cooling and stiffening.

10 - deburring

Finishing by deburring of the runners with scissors.

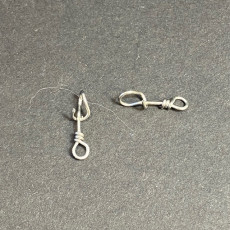

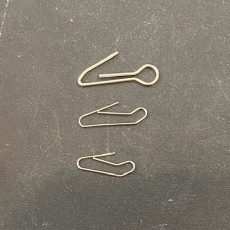

11 - mounting

Mounted on a leaded head. Finish with a point of cyano glue between the head of the lure and the leaded head.

You will find more information by visiting our Bricoleurre workshop.