By Jonathan Soudry on Friday 28 June 2019, 17:05 - Permalink

MANUFACTURING METHOD

1 - Conception of the master

First, a balsa block is cut from the approximate shape of the lure to be made, then the shape is sculpted by turning. Finally, sanding, painting and varnishing are carried out to give shine to the inside of the mould.

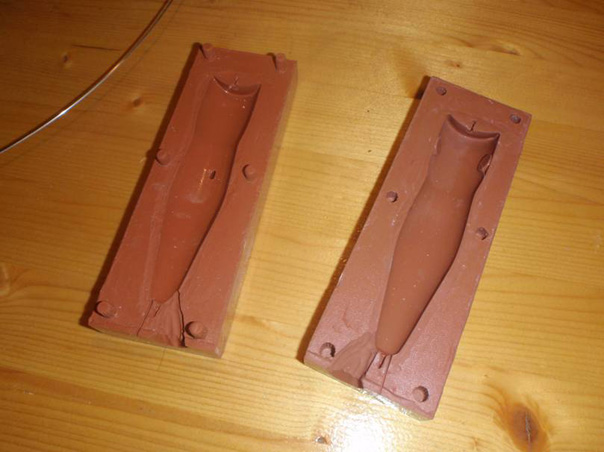

2 - Manufacturing of the double-shell mould

See the manufacturing sheet for a double-shell leaded head. We will obtain a mould in 2 parts.

The position of the casting cone will depend on the shape of the lure. For a popper, it will be located towards the rear end. Vents will be drilled to evacuate the air contained in the mold.

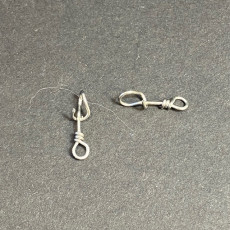

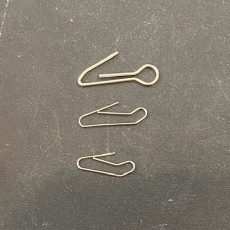

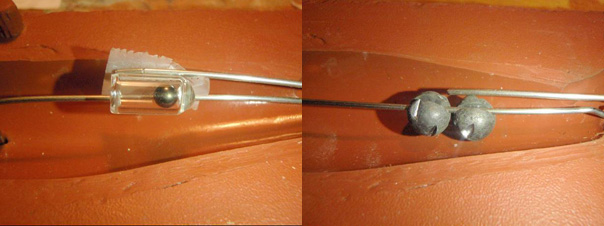

3 - Fabrication of the framework

It will be made with steel wire by bending it with a curling pliers.

A ballast will be placed on this frame to balance the lure. Balancing is important for several reasons, throwing performance, resting in the water and swimming. Rattles may be added.

4 - Making the lure

The principle is : a light or heavy charge is mixed with a two-component resin (A and B). Lightweight to obtain a floating lure, heavy to obtain a flowing lure.

Some technical data:

- The density of A+B resins is 1.1

- The density of the light composite filler for Bricorésine is 0.25 (1 g = 4 cm3)

- The density of the heavy composite load for Bricorésine is 2.55

- The amount of light composite filler for DIY to add is, according to our tests, 15% of the weight of A+B

4.1 preparation of the resin (example for a 115 g floating lure):

4.1.1. mix in a cup 50 g of Bricorésine A + 7.5 g of light composite filler for Bricorésine

4.1.2. mix in another cup 50 g of Bricorésine B + 7.5 g of light composite filler for Bricorésine

4.1.3. wait 10 minutes and re-mixt

4.1.4. pour A into B

4.1.5. mix vigorously for 30 seconds

4.2 resin casting

It must be done within one minute of mixing the contents of the 2 cups because gelation starts very quickly. If we wait too long, it will be impossible to fill the mold.

4.3 demolding

It must be done 20 minutes after the casting. Failure to comply with this deadline may result in a deformation of the still fragile lure. The casting cone can then be removed. Sanding will be necessary to remove any trace of the cone.

4.4 painting

It can be done with aerosol cans or with an airbrush. Three coats of clear varnish will be applied.

4.5 decoration

Eyes can be glued with cyanolite glue.