By Jonathan Soudry on Friday 28 June 2019, 17:06 - Permalink

IMPLEMENTATION OF THE BRICOPATE (paste)

1 - preparation of the paste

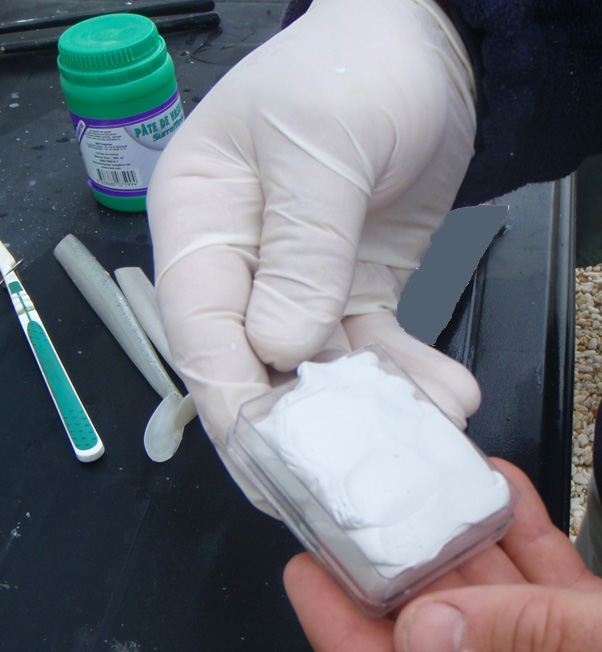

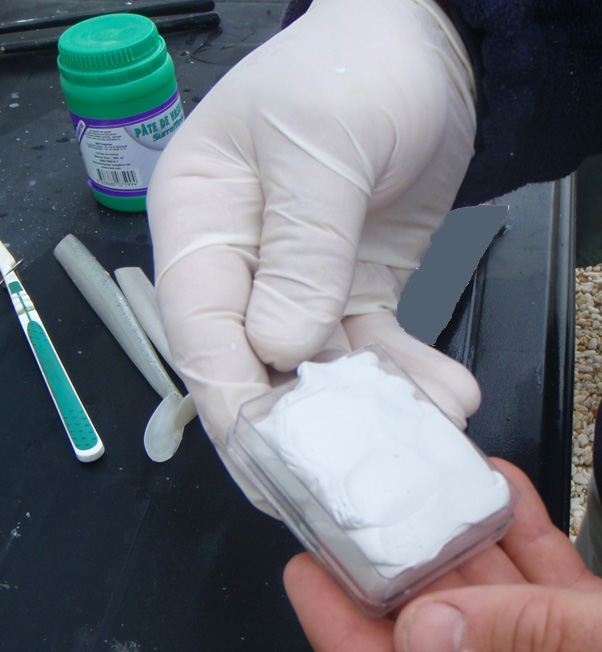

To avoid wasting paste, fill a box adapted to the dimensions of the future mould.

Place the dough in a hand covered with a glove.

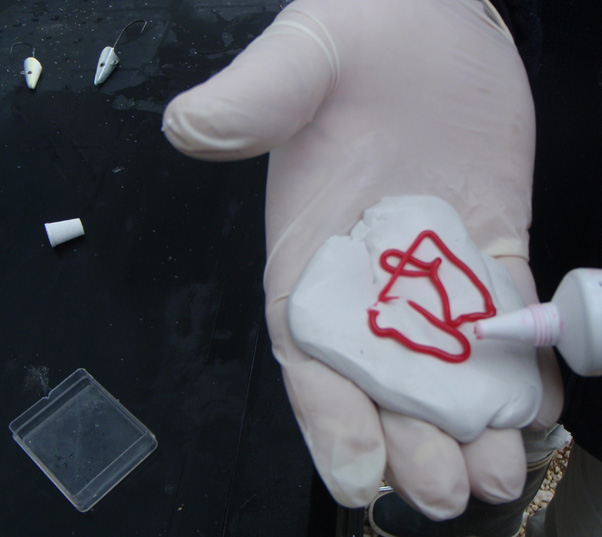

Add the red catalyst in tube: 1 ml per 100g for a hardening in 10 minutes.

Mix well by hand for 2 minutes until the colour of the dough is uniform.

2 - creation of the first hull

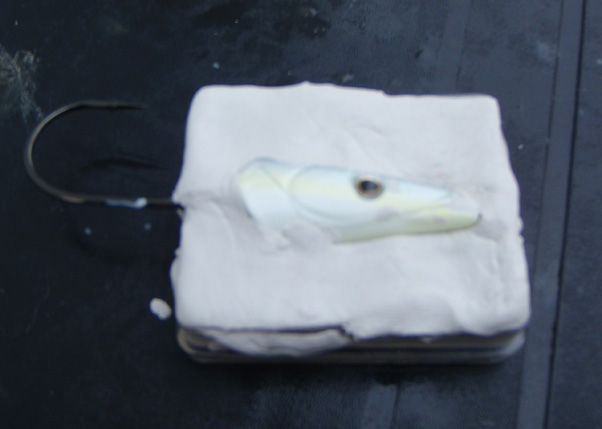

Place the paste in the box.

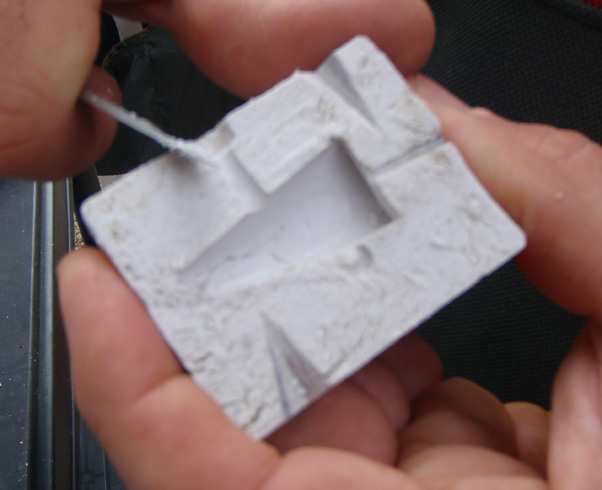

Push half the thickness of the master into the dough.

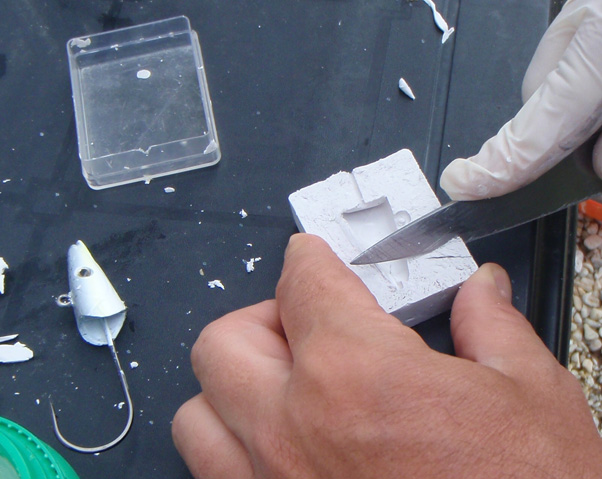

Wait until it hardens. Squeeze the parting line with a sharp knife and remove the first shell from the box.

Cut two notches as a guide to bring the two hulls together.

3 - creation of the second hull

Brush the surface of the first hull with Vaseline (petroleum jelly).

Take the necessary quantity of Bricopâte (paste), place it in a hand covered with a glove.

Add the catalyst in tube: 1 ml per 100g for a hardening in 10 minutes.

Mix well by hand for 2 minutes until the colour of the dough is uniform.

Place the paste in the box.

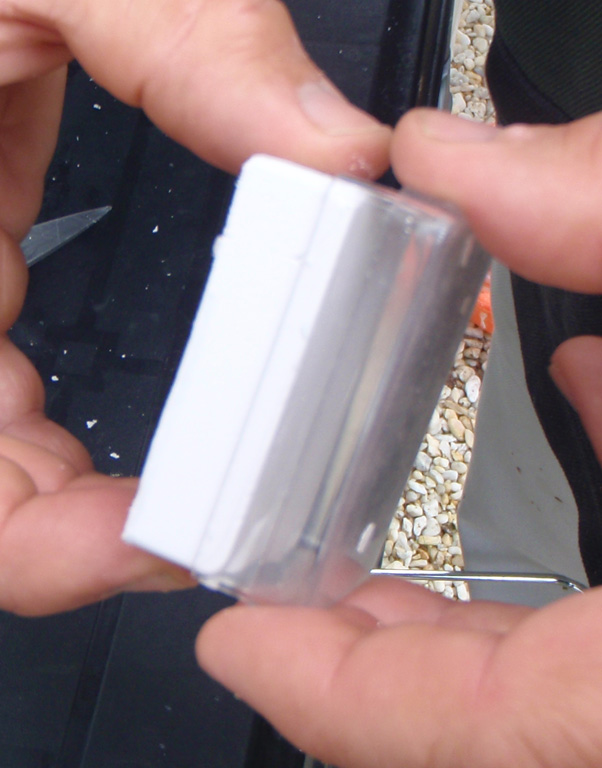

Apply the first shell firmly to the second by overflowing the paste on all 4 sides.

Deburr with a sharp knife.

Wait until it hardens. Remove the second shell from the box.

4 - creation of the casting cone

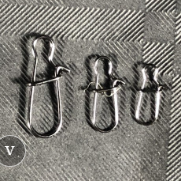

Assemble the two shells with a clamp and drill an opening towards the centre of the mould.

Extend the opening to facilitate the casting of molten lead. The mold is ready.